To determine if your roller shutter motor is dead, you can try the following steps:

Check the power source: Ensure that the motor is properly connected to a power source and that there is a steady supply of electricity. If the power source is not working, the motor will not be able to operate.

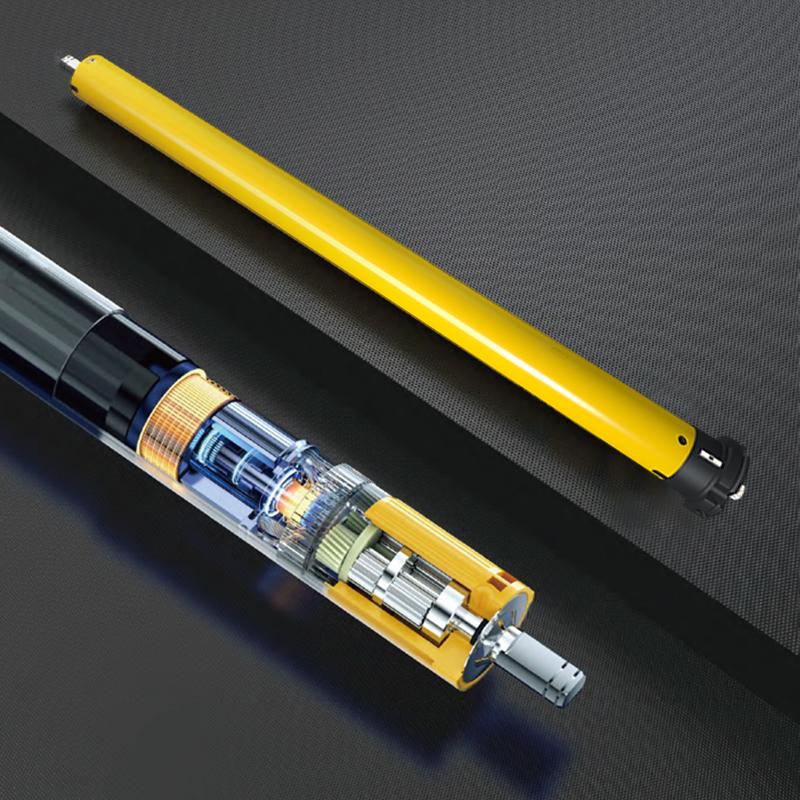

Test the remote control: If the remote control tubular motor is controlled by a remote control, check the batteries and try using a different remote control to make sure it's not the cause of the problem.

Check the motor fuse: If the motor fuse has blown, the motor will not be able to receive power and will not operate. Check the manual to determine the location of the fuse and replace it if necessary.

Check the wiring: Check the wiring that connects the motor to the control system and the power source to ensure that it's properly connected and not damaged.

Listen for any noise: If the motor is not working, listen for any noise that may indicate that it is receiving power but not functioning properly.

If the motor still does not work after checking these items, it may be dead and need to be replaced. In some cases, the motor may be repairable, but it's recommended to consult a professional for a proper diagnosis and repair.

评论

发表评论