There are several ways to use the hot melt machine,

such as spraying, stripping,scraping, etc. The way of gluing is applied

according to the needs of each different industry. Some industries

spray glue, and some industries squeegee glue, which are mainly selected

according to the customer's process requirements.

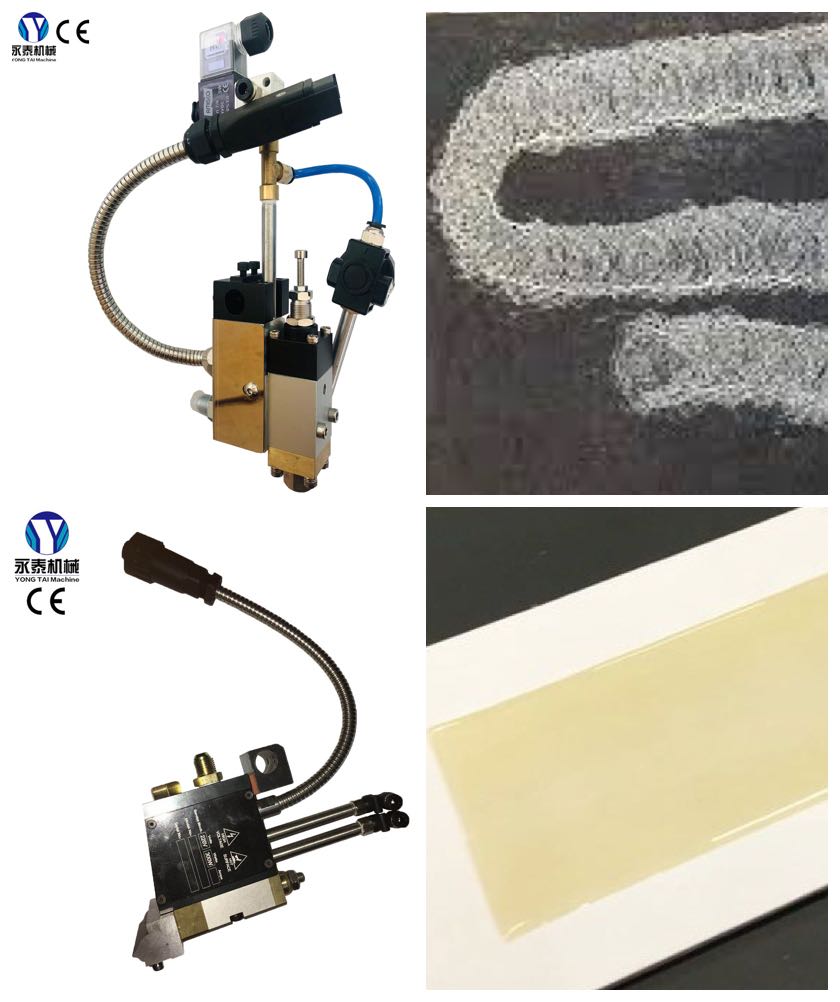

The hot glue guns used for glue spraying and scraping of hot glue machine equipment are different. There are two main differences:

1. The hot melt spraying gun does not need to be in contact with the material, and there is a certain distance. The gun can spray points, lines, circles or different shapes. The scraping type needs to be in contact with the material, and the glue scraped out is wider.

2.In these two ways, the shape of the hot melt adhesive on the material is different. The glue sprayed out is relatively narrow and has a certain thickness, and the surface of the glue is uneven.While the glue that is scraped out is relatively wide, the glue layer is very thin, and the surface is smooth and even. https://www.ytgluemachine.com/

评论

发表评论